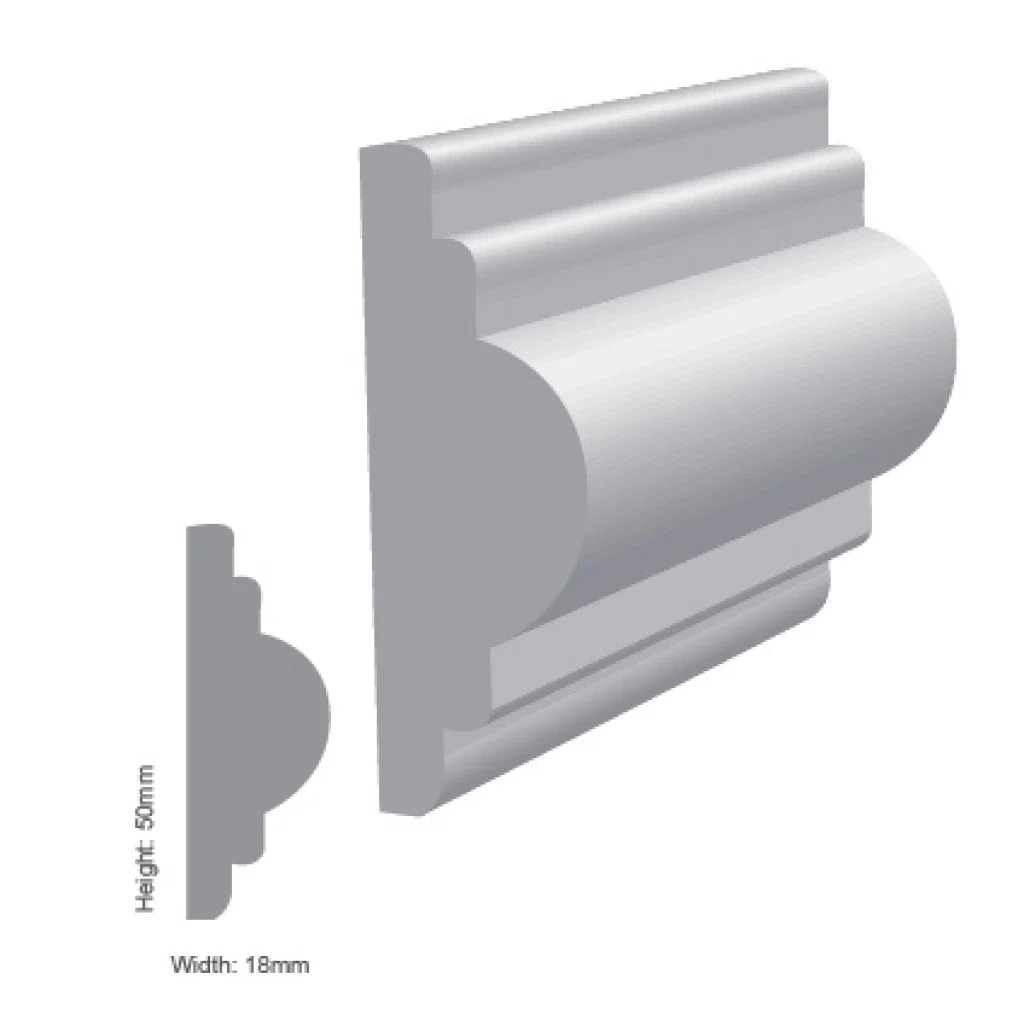

The Trex groove cutter router bit is specially designed to create a groove on the underside of traditional square-edge decking boards, enabling them to be used with the Trex hidden fastening system. this high-quality router bit allows for a seamless, screw-free finish by routing a perfect groove to securely fasten the boards without visible screws. ideal for enhancing the appearance and durability of your deck, the Trex groove cutter ensures an easy, professional installation when converting square-edge boards to grooved boards for Trex decking projects.

FAQs

Trex composite decking is built to last for decades, typically offering a 25-year lifespan or longer with proper care. The material is resistant to many of the issues that affect traditional wood, such as warping, rotting, and splintering.

Yes, Trex composite decking expands and contracts with temperature fluctuations, as with most composite materials. To account for this natural movement, it?s essential to leave a gap between boards during installation. The recommended gap is 5mm to 8mm for end-to-end board spacing and 3mm to 5mm between side edges of the boards. These gaps ensure that the decking can expand and contract without causing buckling or warping.

Trex offers a variety of colours across their decking collections. Some of the available shades include gravel path, Havana Gold, Island Mist, Lava Rock, Rope Swing, Spiced Rum, and Tiki Torch. These colours range from natural wood tones to more vibrant and rich hues, allowing you to find the perfect option for your outdoor space.

Trex composite decking is designed to resist fading due to its durable, capped surface, but slight fading may occur over time due to exposure to the sun. However, it maintains its colour longer than many other decking options.

While Trex composite decking is scratch-resistant, it is not scratch-proof. Heavy furniture or sharp objects can cause scratches. Trex 's surface is designed to withstand normal wear, but it's advisable to avoid dragging furniture or sharp items across it.

Yes, Trex can be used for fascia applications. It is important to use Trex fascia boards designed for this purpose to maintain the aesthetic and durability of your deck's edges.

Trex offers a 25-year limited warranty for residential use, covering material defects, fading, and staining. This warranty provides peace of mind, ensuring that Trex products will perform well for many years.

Trex composite decking is ideal for wet environments like poolside or by the beach due to its moisture-resistant properties. The decking will not absorb water, which helps prevent mould and mildew growth.

Trex composite decking has a Class B fire rating, which means it is resistant to fire spread, making it a safer option for many residential applications. However, it is not entirely fireproof.

Yes, Trex composite decking is made from 95% recycled materials, including reclaimed wood and plastic. This makes Trex a sustainable option for decking, reducing the environmental impact compared to traditional wood.

Trex recommends using screws designed for composite decking, such as those made from stainless steel or coated to resist corrosion. Avoid using regular wood screws as they can cause splitting or rust.

To clean Trex decking, use a mild soap solution and warm water. A soft-bristle brush or mop can help remove dirt. For tougher stains, a composite deck cleaner is recommended. Avoid using harsh chemicals or abrasive tools that can damage the surface.

Trex composite decking consists of a blend of recycled wood fibres and plastic, providing a durable, eco-friendly material. The decking is capped with a protective layer that helps prevent stains and fading while also making it low maintenance.

Trex recommends using the following fasteners for secure and aesthetically pleasing installation:

- Trex hideaway? hidden fasteners: these provide a smooth, screw-free deck surface.

- Trex ? decking screws: these are designed for visible fastenings with stainless steel or coated options to prevent corrosion.

Yes, Trex decking features a slip-resistant surface, which is especially beneficial for pool decks and areas exposed to moisture. The texture helps reduce the likelihood of slipping even when wet.

No, Trex composite decking does not require sealing or staining. The capped surface protects the decking from moisture, staining, and fading, so no additional maintenance like staining or sealing is necessary.

Yes, Trex composite decking expands and contracts with temperature fluctuations, as with most composite materials. To account for this natural movement, it?s essential to leave a gap between boards during installation. The recommended gap is 5mm to 8mm for end-to-end board spacing and 3mm to 5mm between side edges of the boards. These gaps ensure that the decking can expand and contract without causing buckling or warping.